Tribupneu is an advanced engineering concept that integrates tribology, the science of friction and wear, with pneumatic engineering to enhance the efficiency and durability of air-powered systems. By optimizing surface interactions, material selection, and airflow behavior, Tribupneu minimizes mechanical losses caused by friction and component wear. This strategic integration improves energy efficiency, system reliability, and operational performance, making it a valuable approach in modern industrial, automation, and precision engineering applications.

Understanding the Foundations of Tribupneu

To fully appreciate the value of Tribupneu, it is essential to understand the two scientific disciplines it merges.

- Tribology: Examines how surfaces interact when in relative motion. It encompasses friction control, wear resistance, and lubrication strategies. Poor tribological performance leads to energy loss, heat generation, material degradation, and frequent maintenance.

- Pneumatic engineering: On the other hand, deals with the generation, control, and application of compressed air to perform mechanical work. Pneumatic systems are widely used due to their simplicity, cleanliness, and safety, but they are often criticized for inefficiencies caused by air leakage, friction in moving parts, and pressure losses.

Tribupneu unifies these domains, ensuring that pneumatic systems are not only mechanically functional but also tribologically optimized for minimal resistance and maximum operational efficiency.

Why Friction and Wear Matter in Pneumatic Systems

Friction and wear are often underestimated in pneumatic design, yet they significantly impact system performance. In cylinders, valves, seals, and actuators, friction reduces motion accuracy, increases energy consumption, and accelerates component failure. Wear leads to leakage, inconsistent pressure control, and unplanned downtime.

- Optimized surface finishes to reduce contact resistance

- Advanced coatings that minimize wear under repetitive motion

- Material pairings designed to perform reliably under varying pressure and temperature conditions

By managing friction at the microscopic level, Tribupneu enhances macroscopic system reliability and efficiency.

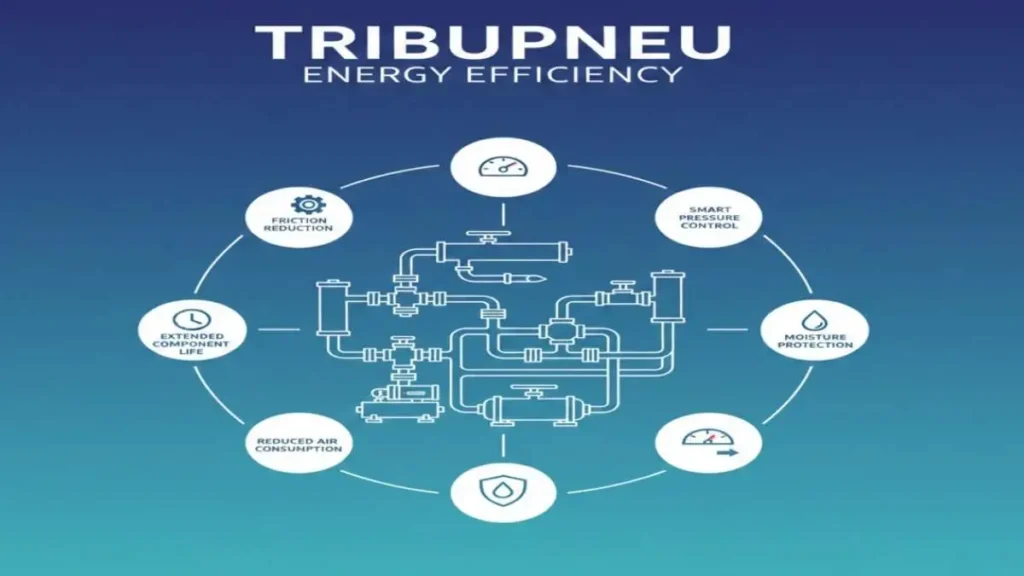

Core Principles of Tribupneu Engineering

Surface Optimization

Carefully engineered surface textures reduce friction while maintaining sufficient sealing performance. Micro-texturing techniques allow controlled lubrication retention, reducing dry contact and surface degradation.

Material Science Integration

The selection of low-friction polymers, advanced alloys, and composite materials plays a critical role. Its systems often employ self-lubricating materials or coatings such as PTFE-based layers, ceramic composites, or diamond-like carbon (DLC).

Lubrication Management

Unlike traditional pneumatic systems that rely on external lubrication, it emphasizes controlled and minimal lubrication. This approach reduces contamination, improves environmental compatibility, and extends component life.

Airflow and Pressure Efficiency

It designs reduce internal resistance, ensuring smoother airflow and more consistent pressure distribution. This directly improves response time and energy utilization.

Performance Benefits of Tribupneu Systems

- Higher Energy Efficiency: Reduced friction lowers compressed air consumption, cutting energy costs and improving overall system efficiency.

- Extended Component Lifespan: Minimized wear significantly increases the durability of seals, valves, and actuators.

- Improved Motion Precision: Smoother surface interactions enable accurate, stable, and repeatable pneumatic movement.

- Reduced Maintenance Requirements: Longer service intervals decrease downtime and maintenance expenses.

Applications of Tribupneu Technology

Manufacturing and Automation

In automated production lines, it-enhanced actuators and valves provide consistent performance under continuous operation. Reduced wear ensures stable cycle times and minimal interruption.

Robotics and Mechatronics

Precision is critical in robotics. It allows pneumatic actuators to achieve smoother, more repeatable motion, making them viable alternatives to electric drives in certain applications.

Aerospace and Defense

Weight reduction, reliability, and efficiency are paramount in aerospace systems. It contributes to lightweight pneumatic controls with extended durability under extreme conditions.

Medical and Pharmaceutical Equipment

Clean operation and low contamination risk make it ideal for medical devices, where controlled motion and hygiene are essential.

Challenges in Implementing Tribupneu

- Complex System Design: Integrating tribological principles into pneumatic engineering requires advanced technical expertise.

- Higher Initial Investment: Specialized materials, coatings, and surface treatments can increase upfront costs.

- Material Selection Difficulties: Choosing compatible low-friction materials for varying pressures and temperatures can be challenging.

- Specialized Testing Requirements: Performance validation demands advanced testing methods and equipment.

Tribupneu and Sustainable Engineering

Tribupneu supports sustainable engineering by reducing energy consumption and extending the lifespan of pneumatic components. Lower friction minimizes compressed air usage, which decreases overall power demand and carbon emissions. Enhanced wear resistance reduces material waste and the need for frequent replacements. Additionally, controlled or minimal lubrication lowers environmental contamination risks. By improving efficiency, durability, and resource utilization, it aligns modern pneumatic systems with long-term environmental and sustainability goals.

FAQs

1. Is Tribupneu environmentally friendly?

Yes, it supports sustainability by lowering energy usage, extending component life, and reducing lubricant-related environmental impact.

2. Does Tribupneu increase initial system costs?

While initial costs may be higher due to advanced materials and coatings, long-term savings from reduced maintenance and energy use often outweigh them.

3. Can Tribupneu be applied to existing pneumatic systems?

In many cases, its principles can be integrated into existing systems through component upgrades and design optimization.

Final Thought

Tribupneu represents a strategic shift in how pneumatic systems are designed and optimized for modern industry. By prioritizing friction control, durability, and energy efficiency, it enables organizations to achieve higher performance with lower operational costs. As industries move toward sustainable and intelligent engineering solutions, it offers a forward-looking pathway that balances innovation, reliability, and long-term environmental responsibility.