Sodiceram is a next-generation, high-performance ceramic material and brand that incorporates sodium-based compounds to deliver exceptional strength, heat resistance, and chemical durability. Designed for both architectural and industrial applications, it blends technical precision with sustainable design innovation.

- Understanding the Science Behind Sodiceram

- Versatile Uses Across Industries

- Comparing Sodiceram with Traditional Ceramics

- Strength and Structural Integrity

- Thermal and Chemical Resilience

- Sustainable Manufacturing and Green Innovation

- Advanced Surface Technologies

- The Future of Ceramic Innovation

- FAQs

- Conclusion

In simple terms, Sodiceram is a durable ceramic solution that combines mechanical endurance, eco-friendly production, and visual versatility. With applications ranging from building façades and tiles to industrial components and decorative pieces, it has become a symbol of how modern materials can balance beauty, resilience, and responsibility.

Understanding the Science Behind Sodiceram

Unlike traditional ceramics, its composition includes sodium-enhanced crystalline structures that reinforce the atomic lattice. This innovation gives it superior tensile and compressive strength, alongside better thermal and chemical stability.

Core Advantages

- Reinforced lattice bonding for higher durability

- Minimal porosity, resisting moisture and cracking

- Thermal shock tolerance, perfect for fluctuating climates

- Corrosion and stain resistance, ensuring long-term beauty

This composition allows Sodiceram to perform exceptionally well in harsh environmental and industrial settings, maintaining performance without compromising design integrity.

Versatile Uses Across Industries

Its adaptability is one of its strongest assets. It supports a wide range of applications, balancing functionality, efficiency, and aesthetic appeal.

Architectural Surfaces

Sodiceram tiles and slabs offer elegance, strength, and low maintenance for walls, façades, and flooring. Architects value its UV resistance and surface texture options, available through digital printing and 3D finishing.

Industrial Environments

Due to its heat and abrasion resistance, it’s widely used in furnaces, processing plants, and insulation systems. It reduces energy loss and extends operational lifespan.

Decorative and Interior Design

Designers love it for custom textures and finishes that replicate stone, wood, or metal. The result is modern luxury with environmental responsibility.

Comparing Sodiceram with Traditional Ceramics

| Feature / Property | Sodiceram | Conventional Ceramics |

| Primary Composition | Sodium-based crystal structure | Clay, feldspar, and silica |

| Strength & Durability | High compressive and flexural strength | Moderate strength |

| Thermal Resistance | Up to 1000°C; stable under shock | Limited resistance to heat cycles |

| Water Absorption | Below 0.2% – almost impermeable | Higher absorption; prone to cracking |

| Chemical Stability | Resistant to acids, salts, and pollution | May degrade with prolonged exposure |

| Sustainability | Energy-efficient and uses recycled content | Conventional firing; less eco-efficient |

Strength and Structural Integrity

Sodiceram’s exceptional strength originates from its engineered sodium-based microstructure, which enhances density, cohesion, and overall surface integrity. This composition provides remarkable resistance against scratching, cracking, and mechanical stress, ensuring durability in high-traffic and load-bearing areas. Even under extreme temperature fluctuations, Sodiceram maintains dimensional stability and a flawless finish. Its non-porous surface minimizes water absorption, lowering maintenance needs while preserving visual elegance. Ideal for façades, flooring, and architectural claddings, Sodiceram offers dependable performance, combining mechanical endurance with long-term structural confidence, making it a trusted material for sustainable modern construction.

Thermal and Chemical Resilience

Sodiceram demonstrates exceptional thermal and chemical performance, sustaining its structure from –50°C to over 1000°C without distortion or damage. Its sodium-enriched composition prevents reactions with acids, alkalis, or salts, ensuring longevity in both indoor and outdoor environments. Resistant to fading and corrosion, it retains its color and texture even after prolonged exposure to UV rays and pollutants. Furthermore, its low thermal conductivity enhances insulation, improving building energy efficiency. This combination of heat resistance, surface stability, and environmental protection makes Sodiceram ideal for laboratories, industrial plants, and energy-conscious architectural designs worldwide.

Sustainable Manufacturing and Green Innovation

Sodiceram’s sustainability philosophy reflects a deep commitment to eco-conscious manufacturing and responsible material sourcing. Its facilities utilize advanced kilns with energy-recovery systems that reduce power consumption and emissions. Recycled inputs such as ceramic waste and glass powders are integrated into production to promote circularity and resource efficiency. Closed-loop water recycling and advanced air filtration further minimize environmental impact. Each tile or slab embodies long-term durability, reducing waste from replacements and repairs. Compliant with LEED and ISO 14001 standards, Sodiceram represents the future of sustainable ceramics where innovation, quality, and environmental responsibility coexist seamlessly.

Advanced Surface Technologies

A hallmark of Sodiceram’s innovation lies in its surface design capabilities that blend artistry with engineering precision.

Digital Printing

- Recreates stone, marble, and natural textures

- Uses UV-stable mineral inks for lasting vibrancy

- Enables bespoke architectural and decorative applications

3D Texturing

- Laser and mechanical embossing create tactile depth

- Improves slip resistance and light diffusion

- Perfect for façades, interiors, and high-end retail environments

Smart Coatings

Optional antimicrobial and self-cleaning layers improve hygiene while minimizing upkeep, a growing demand in hospitality and healthcare spaces.

The Future of Ceramic Innovation

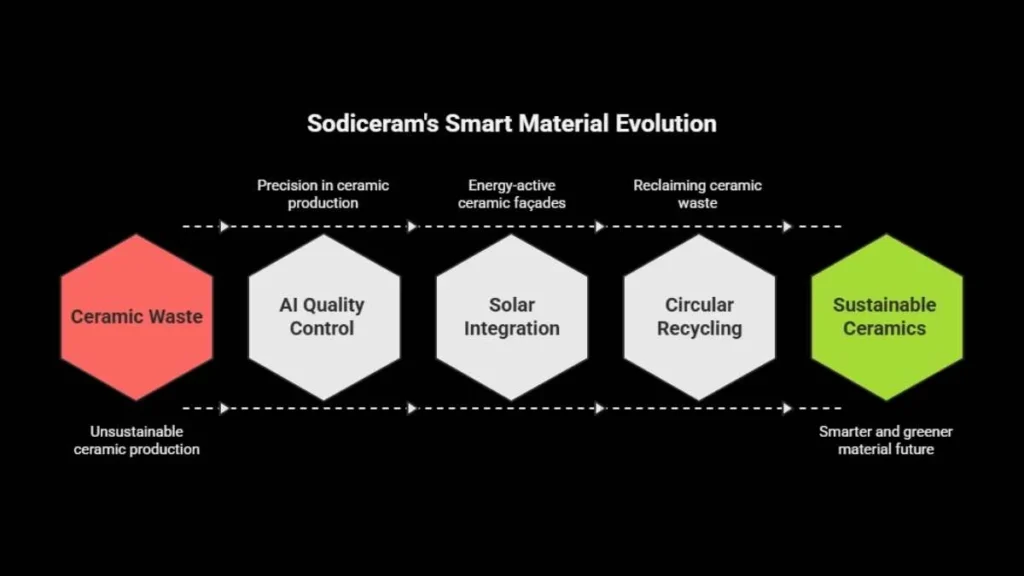

Sodiceram continues to invest in smart material evolution, targeting enhanced sustainability and interactivity.

- AI-guided quality control ensures precision in production.

- Solar-integrated ceramic surfaces are under research for energy-active façades.

- Circular recycling programs reclaim and repurpose ceramic waste.

By merging design, science, and sustainability, Sodiceram is paving the way toward a smarter and greener material future.

FAQs

Q1: Is Sodiceram suitable for outdoor installations?

Yes, its UV and weather resistance make it perfect for façades and open structures.

Q2: Can Sodiceram surfaces mimic natural materials?

Absolutely, digital printing allows lifelike replication of stone, marble, and wood.

Q3: How does Sodiceram support green building certification?

It contributes to LEED points through recycled content, low emissions, and energy savings.

Conclusion

Sodiceram represents the next stage of ceramic innovation, a material that unites durability, design flexibility, and sustainability. Through its sodium-based structure, it delivers superior strength and thermal stability while supporting responsible production.

As global industries seek materials that perform better and last longer, Sodiceram stands as a benchmark for modern eco-engineering. It’s more than a surface; it’s a vision of sustainable strength guiding the future of architecture and design.